Plating Services

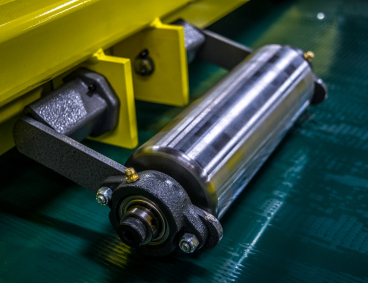

Electroless nickel plating has long been a preferred solution for improved hardness, corrosion resistance and friction resistance in industrial applications. With more than seven decades of plating experience, Electro-Coatings has developed a range of electroless nickel solutions to fit your unique needs.

- Nye-Kote™ – This coating has a high phosphorus content for high wear resistance.

- Kanigen® – Our proprietary electroless nickel plating, in use since the 1950s, is a proven solution for friction and corrosion resistance.

- Nye-Croloy™ – We have combined electroless nickel and hard chrome into a single coating for extreme resistance to corrosion and wear.

- Nye-Carb™ – We add silicon carbide to electroless nickel for added wear resistance.

- Nye-Tef™ – This electroless nickel – PTFE fusion offers a highly slick, no-stick surface.

LARGE TANK CAPACITIES

At Electro-Coatings, we offer solutions for projects large and small. We can meet your high volume or large part plating needs! At our 3 facilities we can easily accommodate your size & specification requirements while also ensuring a quick turnaround and delivery. Our standard plating capabilities include but aren’t limited to:

| SIZES PER LOCATION | ||||

| HOUSTON | CEDAR RAPIDS | BERKELEY | ||

| Electroless Nickel Production | 15’ x 5’ x 6’ 4,000gal 22’ X 48” x 48” 9’ X 36” deep |

5’ x 5’ x 12’ 5’ x 5’ x 5’ |

60” x 48” x 72” | |

| Hard Chrome | 16’ x 4’ x 6.5’ 3’ x 15’ deep |

42” x 9’’ deep 72” x 36” x 40” 40” x 60” x 11’ deep |

12’ x 5’ x 5’ 60” x 19’ deep |

|

*For larger equipment quotes, give us a call and talk with a plating expert to customize to your project requirements.

Since every problem is unique, we adjust our coatings to match the precise challenges you face. Contact us and we’ll engineer a solution to your needs.

protect parts from wear, friction and corrosion

Components used in industrial applications often encounter punishing conditions. Engineers looking to protect parts from wear, friction and corrosion have discovered that electroless nickel plating offers a range of advantages.

Different compounds and formulas can produce an electroless nickel coating with particular attributes. In business for nearly 70 years, Electro-Coatings has produced five different solutions for your particular challenges.

- Consistent, even thickness across component surfaces. Our plating leaves behind a predictable, uniform coating for high-precision parts, even intricate shapes.

- Electricity not required. Unlike electropolishing, electroless nickel plating doesn’t require an electrical current during the process.

- Superior corrosion resistance. Electroless nickel plating is often less porous than electroplated nickel and hard chrome, providing barrier corrosion protection to steel.

- Gentle in application. EN Plating can be executed with zero or compressive stress.

- A reduction in surface friction. Our plating is a well-known friction-reducing coating with non-galling properties and inherent lubricity.

- Solderable coating. Our nickel/phosphorus composition applied with a highly active acid flux lends itself to solderability.