Nye-Croloy™

Nickel Chrome Plating, also known as Nye-Croloy™, was created to combine the corrosion resistance of electroless nickel plating with the hardness and abrasiveness offered by hard chrome plating. Nye-Croloy™ or nickel chrome coating services are especially beneficial to equipment or tools that operate in a highly corrosive/wear environment in the oil field and pumping industries.

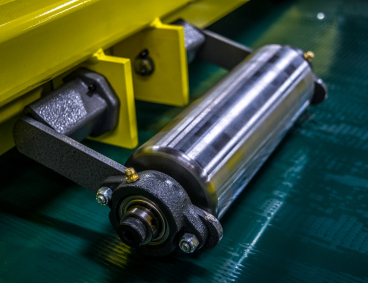

This flourished into a coating that works in almost any application requiring protection from corrosion and wear, including hydraulic cylinders and rods, print cylinders and actuator cylinders, and outer drive units, to name a few.

Industrial hard chrome is one of the industry standards against wear, but industrial hard chrome has a natural microscopic crack pattern. In some applications, such as hydrogen sulfide (H2S) and weak acid exposure, the chlorides can penetrate the cracks in the hard chrome and corrode the base material. Applying a thin layer of electroless nickel plating like Nye-Kote™ or Kanigen® creates a barrier coating, eliminating any corrosive material from attacking and corroding the substrate.

Benefits of Nickel Chrome Coating

- Corrosion resistance - Nye-Croloy™ can significantly improve the corrosion resistance of your base material. Sul-Croloy™ (Sulfamate Nickel/Chrome) has become a popular coating for hydraulic cylinders, rods, or any part that works in very corrosive environments. With the high rates of deposition, damaged parts can be repaired promptly.

- Allows lubricity

- Cost savings due to the coating's resistance in corrosive environments.

Industry Applications

Nickel Chrome Coatings are most frequently found in the following industry applications.

- Oil field

- Petroleum

- Printing

Industrial Application Examples

- Oil tool industry

- Hydraulic shafting

- Printing cylinders

- Actuator cylinders