Nye-Tef™

Nickel PTFE, also known as Nye-Tef™, is a food-grade composite coating solution exclusive to Electro-Coatings, for applications requiring exceptional resistance to friction and peak performance in coating adhesion. PTFE or Teflon is known for its self-lubricating properties, and PTFE coatings are one of the world's most friction-free coatings.

Nye-Tef™ combines the self-lubricating properties of PTFE with the high wear resistant hardness of electroless nickel, and has excellent adhesion which allows for an increased control on uniform thickness. The PTFE coatings self-lubricating properties make it an ideal surface treatment for components and assemblies that cannot use conventional lubricants.

The PTFE in the plated layer provides excellent release from calcium found in hard water areas. In combination with the corrosion resistance of the layer, it offers a solution to the age-old problem of scale build-up on heating elements and sprays nozzles.

Facility Locations

Key Properties for Nickel PTFE Coating

- Low Friction

- Self Lubrication

- Corrosion Resistance

- Wear Resistance

- Uniform Deposit

- Food Grade

Typical Applications for Electroless Nickel with PTFE

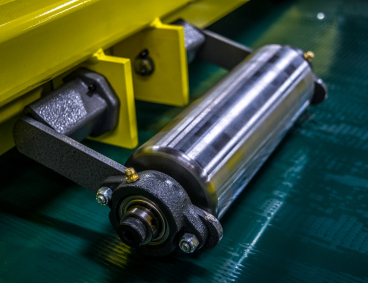

- Food processing equipment

- Sorting equipment

- Injection Molds

- Pump rotors

- Titanium bearings

- Heating elements

The coating chemists and application experts who developed Nye-Tef™ will gladly offer full information and applications advice on its effective use. Contact us to experience our "Yes We Can" spirit on industry's toughest coating challenges.

Electroless Nickel PTFE (Nye-Tef™) Process

Electroless nickel PTFE composite coating consists of an autocatalytic alloy applied nickel/phosphorus matrix containing submicronic particles of PTFE (polytetrafluoroethylene). The PTFE, while soft in its natural form, becomes exceptionally durable when suspended in the nickel matrix. A hardness of 50Rc, combined with the natural friction resistance of Teflon coating, or PTFE, yields a surface that can resist significant abrasion over a long working life.

The coating's non-crystalline molecular structure adds resistance to corrosion and wears due to abrasion. The use of electroless nickel with the ptfe coating surface delivers a coating with excellent adhesion and extremely uniform coating thickness. Documented accuracy to +/- 10% ensures consistent coverage. The non-electrolytic application technology of Nye-Tef™ provides a completely uniform coating, including full coverage of hidden surfaces or intricate geometries.