CHEMICAL INDUSTRY PARTS & COMPONENTS WE HAVE SERVICED:

With more than seven decades of industrial coating experience, Electro-Coatings provides specialty surface finishes to a variety of petrochemical and chemicals processing applications. The following are parts we coat regularly for this industry:

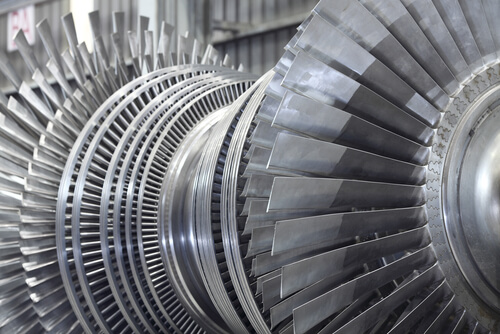

- Turbine Blades

- Pressure Vessels

- Hydraulic Components

- Boiler Tubes

- Chokes and control valves

- Compressor blades & impellers

- Valves

Chemical Industry Metal Coatings

Chemical processing applications transport gases and liquids from one operation to the next using a vast network of tubing, valves and metering devices. Many of these components operate at extreme temperatures and pressures while making contact with corrosive or harsh substances, which can cause unwanted degradation or failure.

Better protect your chemical processing assets with reliable coatings from Electro-Coatings. We are an industrial materials surface finishing provider offering a variety of services designed to meet the needs of the chemicals industry and its suppliers.

- Electroless nickel plating

- Electroless nickel with Polytetrafluoroethylene, or PTFE

- Chrome coatings

- Passivation

- Chromium-over-sulfamate plating

- Sulfate nickel plating

- Metal coatings

- Zinc electroplating

Material protection is necessary when it comes to chemicals processing. Conventional coatings subjected to hazardous or corrosive environments break down more quickly and can produce uneven, rough surfaces that fail to tighten evenly and expose workers to dangers. Electro-Coatings’ advanced coatings create a precise, uniform protective barrier on petrochemical facility equipment, which works to safeguard the substrate from harsh process media. Additional benefits of our coatings include:

- Abrasion resistance

- Heightened employee safety

- Rust protection

- Keep surfaces clean

- Connection gall resistance

The Electro-Coating Advantage

Finding the right coating type and deposition method is the best way to improve the performance of any chemicals processing application. Our in-house design and engineering teams consult with clients to better understand applications and the conditions in which they operate.

We provide solutions to improve performance, extend component lifespan, and ultimately reduce operating costs. Our team partners with customers who have a range of goals, which include:

- Large-scale production

- Research and design

- Small batches

- Prototypes

- Testing and validation

- Original Equipment Manufacturer, or OEM, suppliers

Access to the right components is vital to keep a chemicals manufacturing process online. Failure of one part can force an entire application to shut down. Electro-Coatings has facilities in the United States’ Gulf Coast, West Coast, and Midwest regions, enabling our teams to supply high-quality coated parts without delay. This offers the following benefits:

- Reduced downtime

- Better delivery times

- Boosted productivity

- Improved efficiency

- Lower operating costs

For chemicals processing equipment coating solutions, Electro-Coatings has you covered. For more information, Contact Us.

Electro-Coatings is committed to providing a solution that fits your needs.

Each application comes with the engineering knowledge and coating craftsmanship of an experienced Electro-Coatings staff, working in a facility equipped with the latest technology for precision coating. The result is consistent quality for your industry's most challenging applications, delivered with maximum cost effectiveness.

We understand each job is different, so please contact our trained staff to discuss your specific requirements and learn more about our detailed plating processes, technical details, or plating application information. We'll be glad to show you the difference our "Yes, We Can" attitude makes in coating quality and reliability.