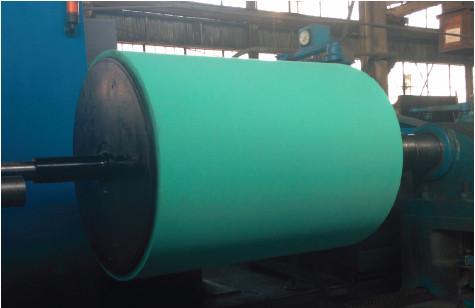

Industrial Roller Fabrication & Reconditioning

Our innovation and skills offer integrated facility services in a wide variety of machinery parts, hydraulic equipment, turbine rotor, pump repair, paper, box, steel mill, food, textile mills, printing, and plastic film industries, just to name a few. Berkeley, CA, location offers Field Repair Services to damaged rolls in your plant and avoid a long shutdown period. Give us a call for more information.

Specialists in Roll Fabrication and Repair

We are the specialist in reconditioning worn or damaged industrial rolls; and in some cases we can manufacture new rolls to original specifications. Years of experience makes Electro-Coatings the one source you can depend upon for the repair of critical tooling.

The common denominator in all of our machining processes is the capacity to handle large rolls. We have made a concerted effort to have the capacity you require, so check us for the processing of your rolls — large or small.

Roller Capabilities/Capacity

For the ever-growing roller and hydraulic services industry, we recondition rollers and hydraulic piston rods utilizing CNC grinding equipment.

Our equipment is capable of handling the following rolls or shafts:

- Grinding – 60" OD X 22’ between centers

- Lathe - 32” swing, 17’ centers max. capacity

- Plating - 60" diameter X 20’ length max. capacity

- Crane Lifting Capacity 20 tons max.