NYE-KOTE™

The high level of phosphorus in electroless nickel plating provides corrosion resistance unmatched by other coatings. The chemical content of high phosphorus electroless nickel plating ranges between 10%-13% & may be adjusted to deliver the level of corrosion resistance desired by an end-user.

Component manufacturers often choose high phosphorus ENP for the high uniformity in coating thickness. Because the coating is transferred to the substrate by chemical reaction rather than an electrical charge (as in electroplating), equal coating density is achieved without respect to the geometry of the object being coated.

Nye-Kote™ is Electro-Coating's exclusive high phosphorus electroless nickel plating. The hardness and highly consistent thickness of Nye-Kote™ (High Phosphorus ENP Services) plated components create extraordinarily smooth finishes & offer a low friction wear surface. By controlling the chemical reaction in the Nye-Kote™, it is possible to deliver highly accurate coating thicknesses, preserving precise component tolerances.

.jpg)

High Phosphorus ENP Services

Behind our craftsmanship stands the technology to precisely control the chemical deposition and heat-treating processes for consistency in results from component to component. At Electro-Coatings, we can plate large and heavy parts of unusual size or high volume and we are prepared to meet your plating specifications & testing requirements. With 3 locations across the United States, we can easily accommodate your project, ensuring a quick turnaround and delivery. We have over 7 immersion tanks offering the capacity to handle any job size and weight. Our tanks range from 4 ft. x 5 ft. x 6 ft. and up to over 40 feet in length.

For larger equipment quotes, contact us to speak with a plating expert today & customize to your project requirements!

Electroless Nickel Plating Benefits

- Uniform Thickness - Controllable within +/- 10% of the desired coating thickness with no variation due to surface configuration.

- Wear Resistance - Combining high hardness and low coefficients of friction.

- Cosmetics - exhibiting a smooth, metallic, unblemished surface that can easily be polished to optical standards

- Corrosion Resistance - Low porosity and non-crystalline structure literally encapsulate substrate material

- Surface Wettability - Nickel enhances capillary action for soldering or brazing.

- Release - with natural lubricating qualities, "sticking" is greatly reduced.

Common Applications

High phosphorus ENP is ideal for the Marine Industry due to its ability to perform flawlessly in harsh environments such as seawater.

Nye-Kote™ is also regularly utilized in the following applications:

- Agricultural Equipment

- Oil & Gas Components

- Steel Mills

- Printing Rolls

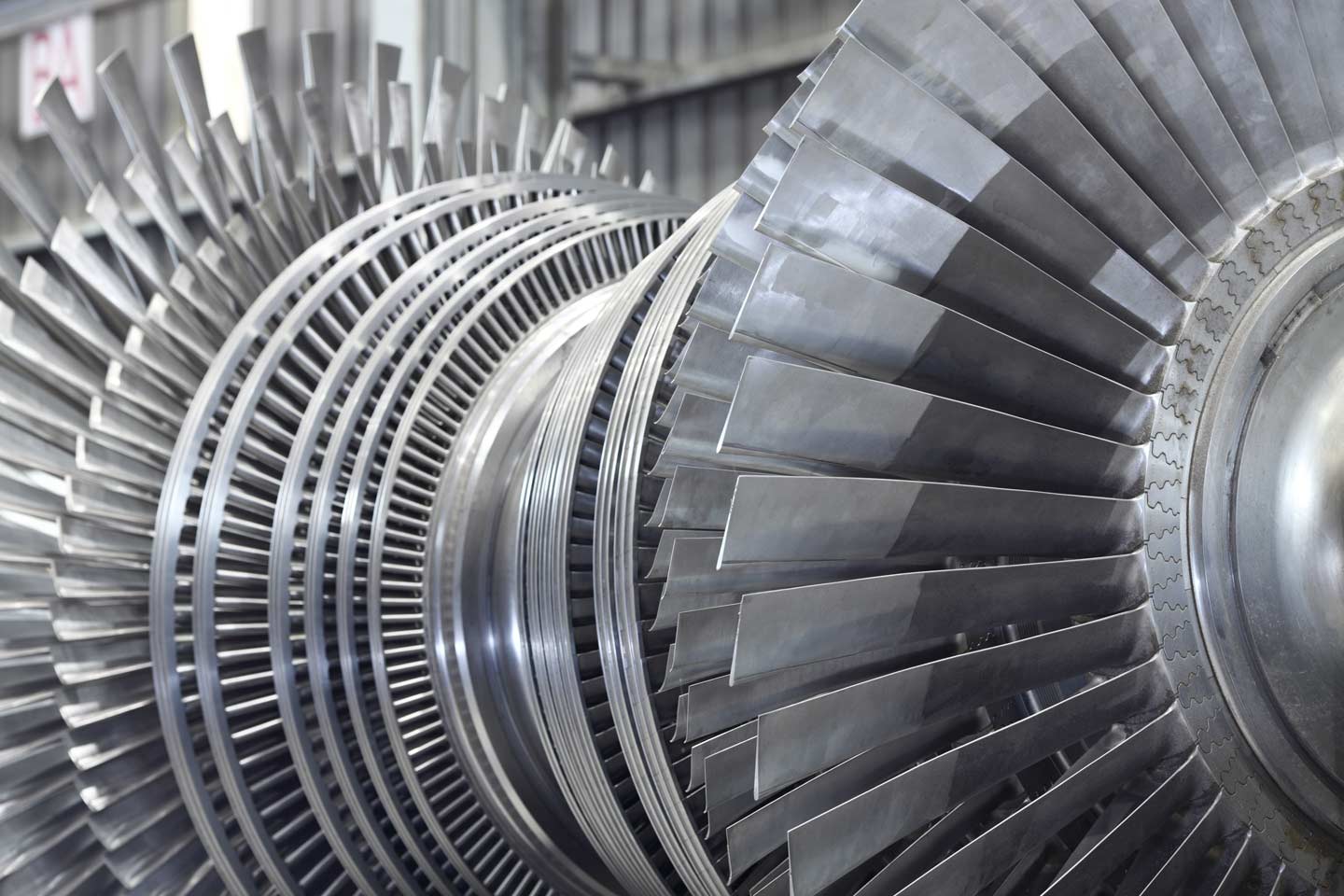

- Turbine Blades

- Pressure Vessels

- Compressor blades & impellers

- Hydraulic Components

- Pistons

- Pumps

- Rotors

- Boiler Tubes

- Valves

- Other industrial applications

Applied By Experts

As both the developer and sole applicator of Nye-Kote™, the experts at Electro-Coatings know how to maximize coating quality for peak performance. Their expertise is supported by the technology to precisely control the chemical deposition and heat treating processes for consistency in results from component to component.

Accessing the coating engineers and application experts behind Nye-Kote™ is as easy as a phone call to Electro-Coatings. We'd be glad to put our "Yes We Can" engineering spirit to work on a specific coating challenge, or to expand your knowledge on the range of possibilities in electroless nickel coatings.