Industrial Roller Services

Reconditioning Worn or Damaged Industrial Rollers

If your industrial rollers have run their course, Electo-Coatings of California Inc. is ready to help.

Electro-Coatings’ plant in Berkeley, California specializes in designing, fabricating, and reconditioning a wide range of rubber and metal-covered industrial rollers.

We offer a comprehensive slate of services that can revitalize, refresh and renew your old, worn, and broken industrial rollers.

Electro-Coatings of California can:

- Recover, recoat, and resurface rollers

- Recondition rollers

- Repair rollers

- Replace roller

- Balance rollers

- Build new cores

- Design rollers

- Manufacture rollers to original specifications

Utilizing our innovative, precise roller equipment, Electro-Coatings delivers high-quality, cost-effective repairs, industrial roller reconditioning, and recovering of your industrial rollers that will reduce your costs, improve your efficiency, and increase the quality of your plant operations.

What Are Industrial Rollers?

Industrial rollers make modern manufacturing go round.

Rollers, coupled with high-speed sorting equipment, help handle materials and move products. Some rollers touch materials, others don’t. There are roller systems used for almost every type of industrial application.

What Are Industrial Rollers Used For?

Industrial rollers are used in an array of manufacturing equipment, particularly:

- Stamping presses

- Conveyor systems

- Bending machines

- Printing presses

- Sorting systems

- Package moving systems

Providing The Services You Need

Electro-Coatings of California Inc. are experts in industrial roller technology. Our high-quality, cost-effective industrial roller services add value to components both before and after the coating process. Our innovative roller equipment can service the following dimensions for rolls or shafts:

- Grinding: 60" Diameter X 22’ between centers

- Lathe: 38” Diameter X 20’ between centers

- Plating: 60" diameter X 20’ long

- Crane Lifting Capacity: Up to 10 tons per crane

We Recondition, Recover and Repair Almost Every Type of Industrial Roller:

- Rubber

- Metal

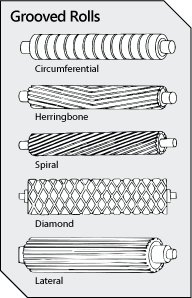

- Grooved Rollers

- Types of Grooved Rolls

- Specialty Rollers

- Industrial Compound Rollers

- SBR Rubber

- Silicone

- Polysulfide Thiokols®

- Nitrile® Buna N

- Neoprene® Chloroprene

- Hypalon®

- Ethylene Propylene

- Natural Rubber

- Fluoro Elastomer

- Hard Urethane

- Urethane

- Nylon and Teflon®

Electro-Coatings: Your Perfect Industrial Coatings Partner

For more than 70 years, Electro-Coatings has provided high-quality, long-lasting electroless nickel plating and other industrial coating services for both large components and small components. We have a drive and passion to take on plating and coating challenges because we have the experience, expertise and equipment to deliver exceptional results.

Electro-Coatings offers:

- Three locations across the nation: Texas, California, and Iowa.

- Substantial production capacity.

- Logistical flexibility to minimize shipping time and costs.

- Industry-leading range of proprietary coatings & electroless nickel plating.

- State-of-the-art equipment is scaled to coat components of all shapes, sizes, weight, length, and volume.

- Advanced experience in many traditional coating types.

- In-house support services that minimize outsourcing.

- Complete finishing services, including balancing, magnafluxing, sandblasting, grinding, machining, blasting, honing and passivation.

Experts in roll technology

Electro-Coatings backs it's Yes We Can spirit of customer helpfulness with services that add value to a component both before and after the coating process.

We are experts in roll technology and reconditioning of worn or damaged rolls and in some cases we manufacture new rolls to original specifications. Years of experience plus the latest technologies located at our Berkeley, CA facility, make Electro-Coatings the one source you can depend upon for the repair of your industrial rolls. In some cases we can repair damaged rolls in your plant, minimizing your downtime.

The common denominator in all of our machining processes is the capacity to handle large rolls. We have made a concerted effort to have the capacity you require, so check us for the processing of your rolls - large or small.

For the ever-growing roller and hydraulic services industry, we recondition rollers and hydraulic piston rods utilizing CNC grinding equipment.

Our equipment is capable of handling the following rolls or shafts:

- Grinding – 60" OD X 22’ between centers

- Lathe - 32” swing, 17’ centers max. capacity

- Plating - 60" diameter X 20’ length max. capacity

- Crane Lifting Capacity 20 tons max. capacity

- Machinery Parts

- Hydraulic Equipment

- Turbine Rotor

- Pump Repair

- Box

- Steel Mill

- Food

- Textile Mills

- Paper

- Printing

- Plastic Film Industries

- just to name a few...

- Design

- Hard Surfacing

- Core Building

- Static Balancing

- Core Repair

- Dynamic Balancing

- Journal Repair

- Smooth

- High Polish

- Micro Polish

- Matte

- Rough

- Grooved

- Crowned

- Barreled

- Textured

- Patterned

- Long nap (fiber-filled)

- Short nap

- Crepe

As part of Electro-Coatings of California quality system, an inspection specification sheet is completed on all rolls within 48 hours. Specifications are confirmed and changes are noted and communicated to the customer. A final inspection is completed prior to ship date. Attached is an example of the final inspection sheet that is sent via hard copy and electronically to the appropriate customer contact.

- Corrugating Glue Metering Rolls

- Roto gravure Cylinders