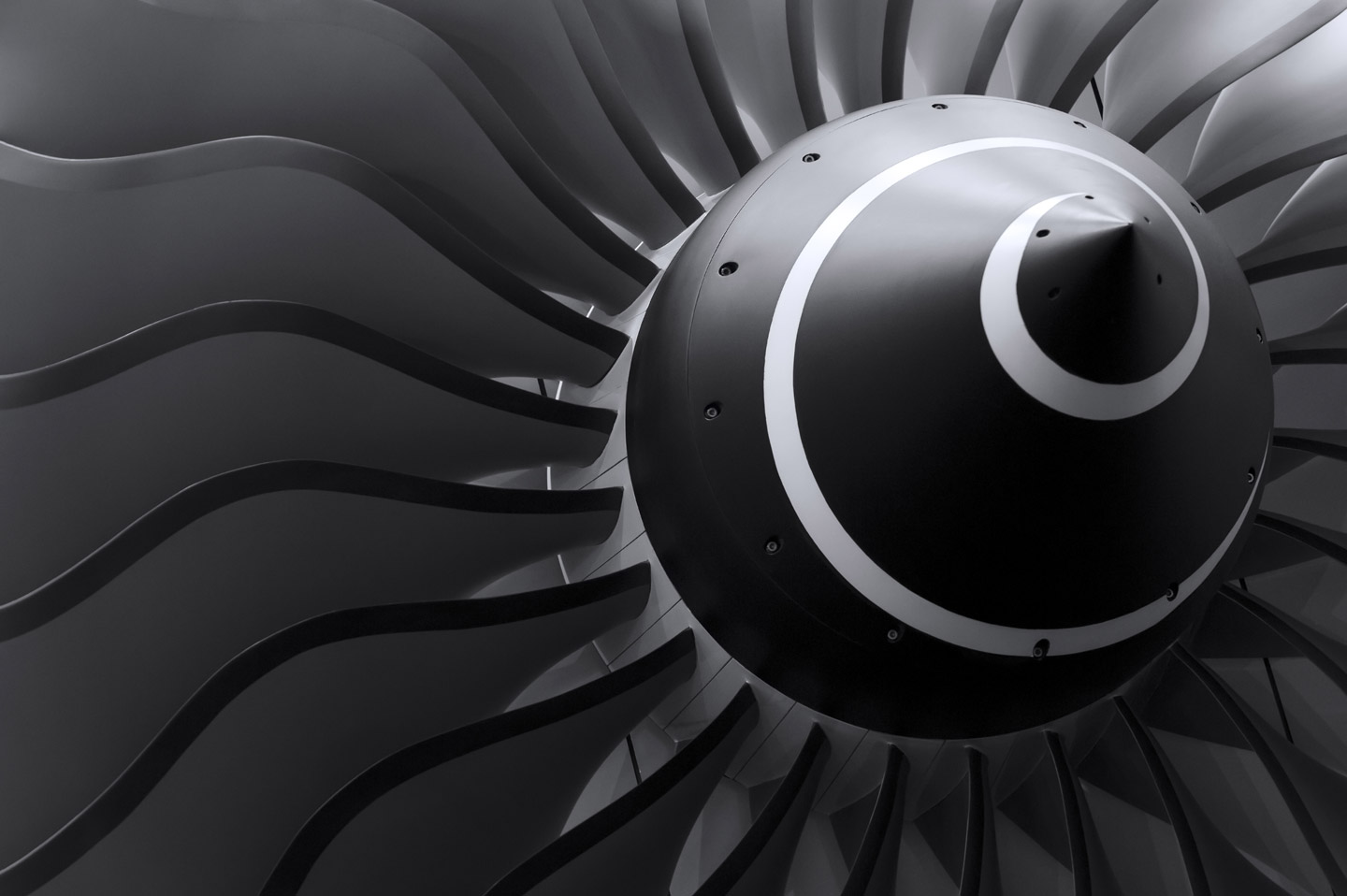

Coatings for the Aviation Industry

Electro-Coatings is committed to providing a solution that fits your needs.

In the aerospace industry, the production quality of aircrafts and aircraft parts must be the highest possible. Reliability and security in parts is essential for not causing a disastrous accident. Electro-Coatings offers years of experience in aerospace nickel plating.

Electroless nickel plating provides a metal coating via chemical reaction. It gives a more even, uniform coating for hard-to-reach areas on the surface of a part. Nickel is generally the metal of choice in the aerospace industry when it comes to manufacturing. Different types of nickel alloys used in electroless nickel plating will yield different results, read more below.

High phosphorous (10-13%):

The best corrosion protection and resistance in highly acidic environments

Medium phosphorous (5-9%): Nye Kote

This alloy is best when appearance is a primary objective.

Low phosphorus (less than 5%): Kanigen LP24

Provides increased surface hardness and exceptional solderability, as well as the best resistance in alkaline environments.

We understand each job is different, so please contact our trained staff to discuss your specific requirements and learn more about our detailed plating processes, technical details, or plating application information. We'll be glad to show you the difference our "Yes, We Can" attitude makes in coating quality and reliability.