Electroless Nickel Plating Services in Texas, California, & Iowa

The process of adding an electroless nickel plating to a metal surface is an autocatalytic chemical reduction. This means that instead of using an outside source of electricity like in the similar electroplating process, the electroless nickel plating process uses a chemical bath to deposit a nickel / phosphorous layer onto the metallic surface. A surface coated in electroless nickel can even be used on non-conductive surfaces which allows for plating of a wider variety of base materials. This electroless process greatly improves the object's resistance to galling and leaves a predictable, uniform nickel coating for high-precision parts, which can be applied to both ferrous and non-ferrous surfaces of any geometry or intricate shape. Our electroless nickel plating processes are compliant with ASTM B733, Mil-C-26074E, AMS 2404B, & AMS 2404E industry standards.

Our Electroless Nickel Plating Experience

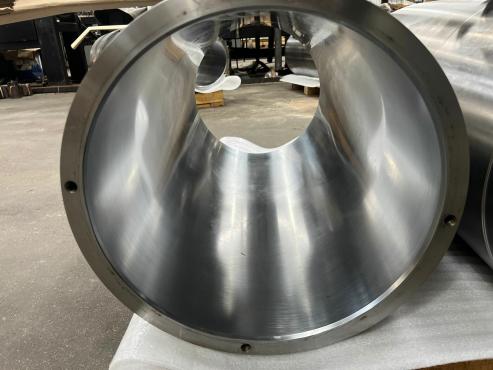

With over 70 years of plating experience, Electro-Coatings offers a wide range of electroless nickel coatings based on your application's needs, including large components and small components (i.e. tanks and ball valves). Our willingness to tackle plating and coating challenges is important, but only when paired with the capability to deliver top quality results. Electro-Coatings offers both, along with the experience and facilities to deliver a product cost-effectively.

Types of ENP Processes

CHOOSE AN ENP PROCESS

Select an option below to learn more about the process.

FILTER BY LOCATION

ABOUT

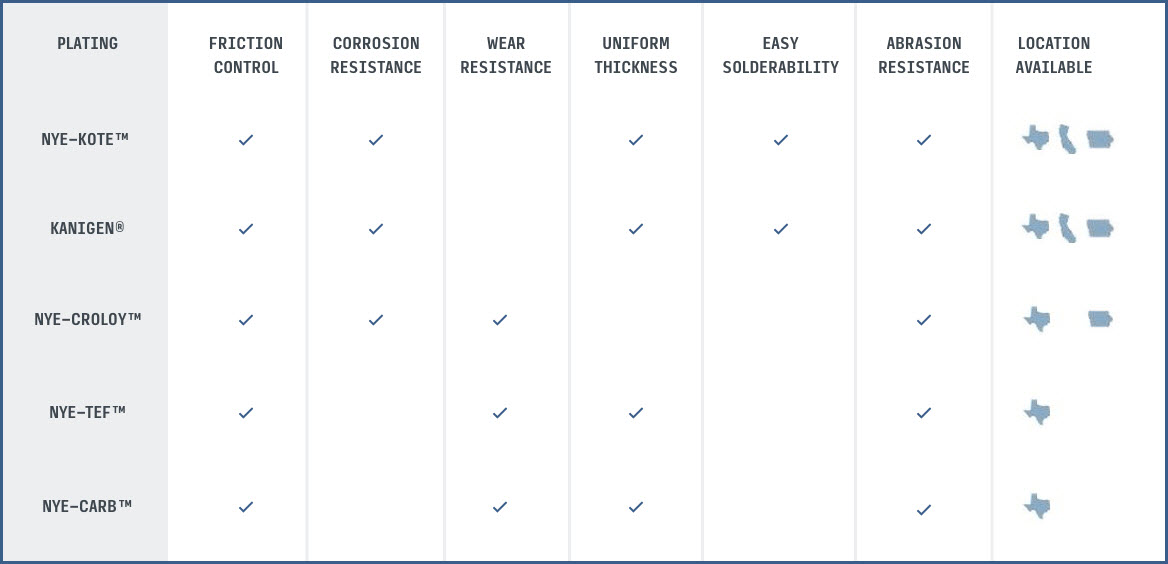

Nye-Kote™

Nye-Kote is an excellent option if you're looking for high phosphorous electroless nickel plating that offers corrosion resistance for agricultural, steel mills, oil and gas, and other harsh environments.

Features

- Friction Control

- Corrosion Resistance

- Uniform Thickness

- Easy Solderability

- Abrasion Resistance

ABOUT

Nye-Croloy™

Nye-Croloy™ is our electroless nickel and hard chrome coating designed to provide highly corrosive environments, such as oil field and pumping applications, with superior wear resistance.

Features

- Friction Control

- Corrosion Resistance

- Wear Resistance

- Abrasion Resistance

ABOUT

Nye-Tef™

Our electroless nickel and PTFE plating offers fiction resistance and excellent adhesion, allowing for increased control on uniform thickness.

Features

- Friction Control

- Corrosion Resistance

- Wear Resistance

- Uniform Thickness

ABOUT

Nye-Carb™

Our electroless nickel and silicon carbide coating offers best wear resistance for used precision parts such as pipes and components that have complex geometries

Features

- Friction Control

- Wear Resistance

- Uniform Thickness

- Abrasion Resistance

ABOUT

Kanigen®

Our exclusive electroless nickel coating has provided friction control and corrosion resistance for almost 50 years.

Features

- Friction Control

- Corrosion Resistance

- Uniform Thickness

- Easy Solderability

- Abrasion Resistance

Benefits of Electroless Nickel Plating

Components used in industrial applications often encounter punishing conditions. Electro-Coatings provides five different types of electroless plating, and though they are mainly dependent on the amount of phosphorus present in the chemical bath, they each provide unique on-the-job performance advantages. These unique advantages include wear/corrosion resistance, friction resistance, and the uniformity of the coating.

Electroless Nickel Plating Specifications

Applicable Electroless Nickel Plating Base Metals

- Iron

- Nickel

- Brass

- Steel

- Copper

- Aluminum

- Stainless Steel

Levels of Phosphorus in Electroless Nickel Plating

As mentioned above, there are different types of electroless nickel that are used for electroless nickel plating that contain varying levels of phosphorous – low, medium and high – for different applications.

The most commonly used type of electroless nickel contains medium levels of phosphorus, also called MPEN. MPEN contains anywhere from 5% and 9% phosphorus. Processes using this type of EN have high-speed deposit rates as well as bright and semi bright options. Low phosphorus electroless nickel (under 5% phosphorus) provides parts and configurations with uniform thickness on the inside to eliminate grinding after plating has been completed as well as alkaline corrosion resistance. Electroless nickel with highest amounts of phosphorus – anywhere from 10% to 13% - are used in oil drilling and coal mining and other applications where a high level of corrosion resistance is needed for protection against highly corrosive acids.

Industries Served

Electroless nickel plating are used to provide protection from wear and abrasion, resistance against corrosion, and add hardness to parts of all conditions. It’s commonly used in coatings applications in engineering, aerospace, oil and gas, construction, electronics and several others.

Plating Process of Electroless Nickel

Learn More

Electroless Plating vs. Electro-Plating

Learn More

Plating Services

Learn MoreFrequently Asked Questions

Why Choose Electroless Nickel Plating (ENP)?

Electroless nickel plating provides large flexibility of thickness and volume of the plating on metal services can easily fill recesses or pits in the metal services. This allows for a wider variety of industrial parts that can be finished with a uniform surface, including oil field valves, valve pumps, driveshafts, electrical/mechanical tools, and engineering equipment.

What is the difference between nickel plating and electroless nickel plating?

Electroless nickel plating is less porous than electroplated nickel and provides a barrier of corrosion protection to steel. It can be applied with zero or little compressive stress making it gentle in application.

Is electricity required for electroless nickel plating?

No electricity is required for ENP, making it a more accurate and efficient and cost-effective coating process. It can be completed with less equipment and fewer coats than electroplating to create a stronger, high-quality finish.

What is the hardness for electroless nickel plating?

Electroless nickel plating has a hardness of between 68 and 72 on the Rockwell C Scale.