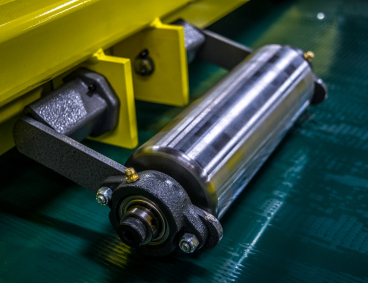

Abrasion Resistant Coatings

Abrasion, also known as grinding or wearing away due to friction, is a factor on any industrial part, no matter the hardness. Abrasion resistant coatings help to minimize the effect of friction on the outer surface of metal parts. We offer four different options for your abrasion resistant coating solutions. Contact us for an application-specific coating recommendation.

Abrasion resistant coatings offer bonus performance benefits.

With the Electro-Coatings family of abrasion resistant coatings, hardness is only the beginning. Each of our four options help components maintain more conformity with specified dimensional tolerances, while maintaining a profitable mix between bond strength, coverage reliability, dimensional stability and cost effectiveness.

Every coating is backed by the expertise of an Electro-Coatings applications specialist, ready to help you choose the technology that delivers the best balance between performance, quality and affordability.

Abrasion resistant coatings we offer:

Electralloy™ Thin Dense Chrome Plating

Learn More

Kanigen®

Learn More

Nye-Kote™

Learn More