Wear Resistant Metal Coatings

Surface hardness is one of many benefits delivered by the Electro-Coatings family of wear resistant coatings. Each of our three options help components maintain closer conformity to specified dimensional tolerances.

Behind each wear resistant coating option stands an Electro-Coatings applications specialist, ready to help choose the coating technology that strikes the best balance between performance, quality and cost-effectiveness.

How Electroless Nickel Plating offers Wear Resistance

Nye-Carb™: Silicon Carbide Plating (Nye-Carb™: Electroless Nickel + Silicon Carbide)

The extreme hardness of silicon carbide...approximately 9 on the Mohs scale, compared to 10 for diamond...makes Nye-Carb a wise choice for components that bear heavy loads in the absence of consistent lubrication. Few surfaces of any type can match the wear resistance of Nye-Carb™, a chemically applied silicon carbide coating that suspends microscopic, highly uniformly sized particles of silicon carbide in a matrix of electroless nickel (90-93% nickel, 7-10% phosphorus.)

Electralloy™ Thin Dense Chrome Plating

Learn More

HVOF: High Velocity Oxy-Fuel

Learn More

Wear Test Data

Learn MoreHard Chrome Plating

For resistance to indentation, scratching, bending or shearing, few coatings can match the strength of Electro-Coatings hard chrome plating. The surface delivers durability through a coefficient of hardness that is among the highest of all metal coatings.

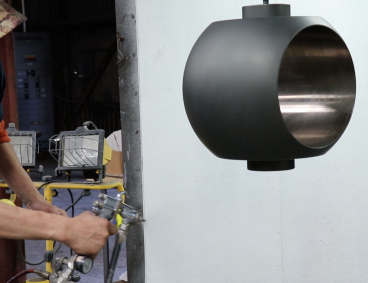

HVOF Spray-on Coating

The High Velocity Oxy-Fuel (HVOF) coating application process increases the wear resistance of many types of Electro-Coatings protective coatings, while delivering extra bond strength for longer component life.

Wear Resistance Test Data

This report presents the results of Taber Abrasion test conducted on samples of coated steel plates. The testing data analysis was completed on March 21, 2008.